With its relatively light weight and wide range of available shapes, cold-formed steel framing offers a cost-effective and efficient solution to provide structural support for many complex architectural building features including:

- Load bearing framing for walls, roofs, floors and platforms

- Non-load bearing structural backup for exterior veneer systems

- Framing for shear walls & bracing as part of a building’s lateral load resistance system

- Framing for interior partition walls, ceilings, soffits and bulkheads

Some of our recent cold-formed steel framing projects include:

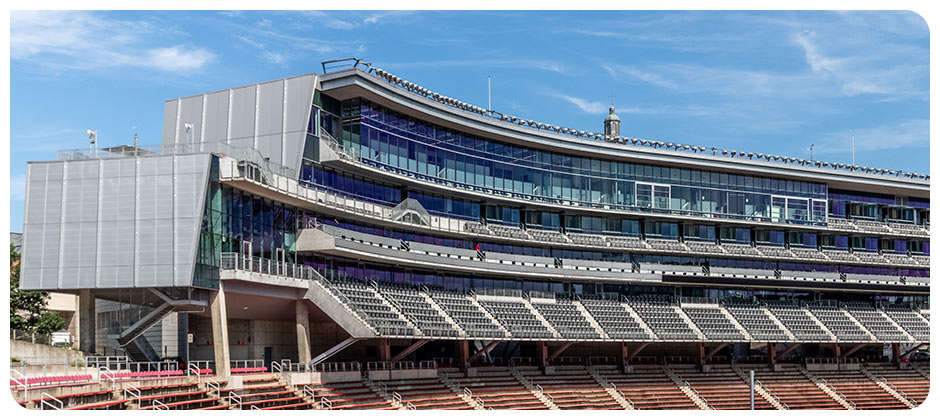

University of Cincinnati Nippert Stadium Renovation | Cincinnati, Ohio

The University of Cincinnati has renovated and expanded its football stadium, increasing its capacity from 35,000 seats to over 40,000. As the second oldest college football play site in the nation, it was imperative to renovate and maintain the historic on-campus setting, consistent with the “old-time stadium charm”. The majority of the renovation, and Schaefer’s specialty engineering, took place along the west side of Nippert Stadium, with a new four-story pavilion structure complete with club seating, corporate and private suites, an outdoor patio, and upgraded press box facilities.

Schaefer designed the cold-formed steel framing system to support the metal panel veneer system and portions of the curtain wall glass that make up the cladding system for the new pavilion structure. As we found out through the design process, upgrading the best seat in the house came with some unique challenges:

Schaefer designed the cold-formed steel framing system to support the metal panel veneer system and portions of the curtain wall glass that make up the cladding system for the new pavilion structure. As we found out through the design process, upgrading the best seat in the house came with some unique challenges:

- Sloped exterior walls resulted in combined stresses on all exterior framing and connections

- Cantilevered edge of slab connections supporting multiple stories of cold-formed steel framing and metal paneling

- Jambs for louvers and window openings that are sloped in multiple directions resulting in complex loading on the framing and connections to the main building structure

- Horizontal truss and inverted shear walls required to frame portions of exterior wall system around a suspended stairway

The new pavilion structure will provide coaches, media personnel and spectators with a whole new perspective of the on-field action. After a full season without football on campus, the improved stadium will be packed for the first kick-off of the 2015 football season.

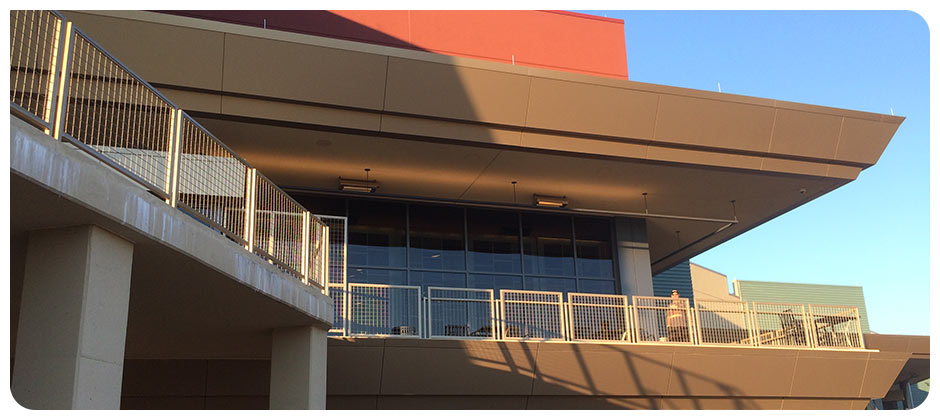

Belterra Park Gaming & Entertainment Center | Cincinnati, Ohio

Previously River Downs Gaming Park, Pinnacle Entertainment purchased the outdated racetrack and gaming center with plans to rebrand and renovate. Schaefer was a part of the renovation of the only dirt racetrack in Cincinnati and the construction of the new racino facility complete with grandstand seating, suites, a gaming floor and dining areas for six new restaurants.

As the cold-formed steel framing specialty engineer on this project, Schaefer designed and detailed exterior wall and canopy framing to support veneer finishing, interior framing for walls up to 30 ft tall, self-braced interior walls, and interior suspended wood ceilings, wood truss elements, and radiuses soffits and bulkheads throughout the new gaming floor.

We were able to work with the contractor to phase the shop drawings submittals to maintain a tight schedule and keep work moving on the project. The high clear span of the interior walls and complex geometry around the front entrance and exterior canopies provided some unique design challenges along the way.

We were able to work with the contractor to phase the shop drawings submittals to maintain a tight schedule and keep work moving on the project. The high clear span of the interior walls and complex geometry around the front entrance and exterior canopies provided some unique design challenges along the way.

Cincinnati Children’s Hospital Medical Center, Location T | Cincinnati, Ohio

The Cincinnati Children’s Hospital Medical Center recently expanded its campus with a new 14-story clinical research tower which will house new and innovative laboratory and research space. The hospital hopes to use this new space to help attract and retain the leading minds in pediatric health care as well as to further enhance and develop the cutting-edge technology already being used at the hospital.

Schaefer provided the design, detailing and shop drawings for all of the exterior cold-formed steel framing. Cold-formed steel studs provide extreme versatility for wall framing applications such as this. Individual pieces are easy to create, erect and are extremely compatible with the steel and concrete framing of the main building. Several faces of the building’s façade were sloped walls which required significant design coordination between the architect of record, the cold-formed steel stud contractor and Schaefer. The signature exterior design element of the building, an oculus opening in the top floor’s exterior wall, is curved in two directions. The details for this feature were hand-sketched and coordinated in multiple planes to ensure that the erection and installation of the studs and the exterior skin was executed with ease. This is an excellent example of the collaboration between Schaefer, acting as the specialty engineer, the stud supplier, and the project design team. The collaboration between all parties was vital to the successful installation of this key design feature.

We have a core group of engineers dedicated to providing cold-formed framing design services. This expert team stays up to date on the latest shapes, connections and framing systems that provide time and cost savings to the contractor. To better serve our clients, the team also collects feedback on which types of members and connections are most efficient and user-friendly for installation.

We have a core group of engineers dedicated to providing cold-formed framing design services. This expert team stays up to date on the latest shapes, connections and framing systems that provide time and cost savings to the contractor. To better serve our clients, the team also collects feedback on which types of members and connections are most efficient and user-friendly for installation.